No Quick Fix: The Surprising Costs of Starting a Pharma Wholesaling Business in the Netherlands

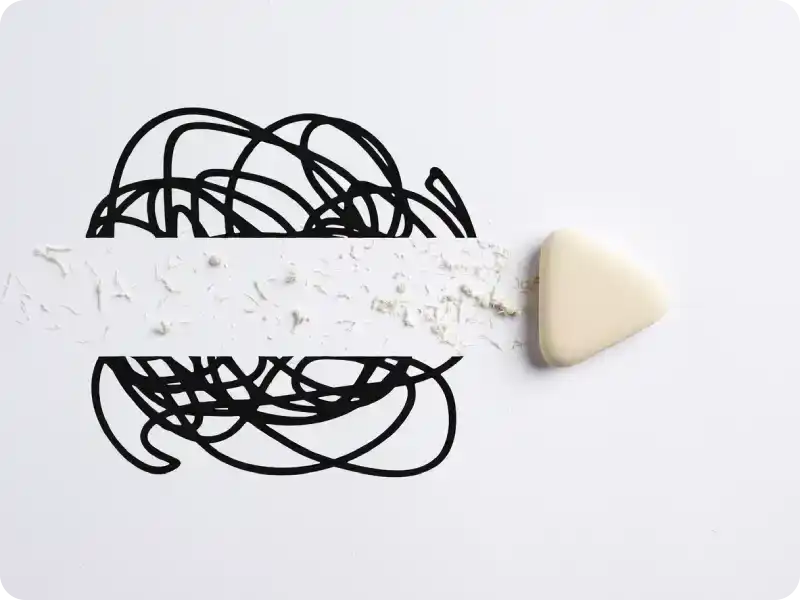

Navigating the complex landscape of obtaining a Wholesale Distribution Authorization (WDA) license is no easy feat, especially for startups. However, cutting corners and attempting to "hack" your way into compliance can lead to severe consequences.

By the skin of one's teeth

At least a few times a year, we are confronted with startups that have their WDA license request denied or receive inspection results that are far below average. Mistakes happen. Misinterpreting the guidelines or forgetting to perform a part of the transport validation could be classified as beginner's mistakes.

However, it's usually not these types of mistakes that occur. There is a worrying trend going on lately: trying to hack your way into obtaining a WDA license—fast, cheap, and by the skin of one's teeth. And it's not only a problem for the few who try this strategy; the WDA holders who attempt to comply with the GDP guidelines as best as they can without resorting to shortcuts also suffer.

Why is the Netherlands so popular?

Since Brexit, a lot of British companies that needed a presence in the EU, chose to set up in the Netherlands. Why? The finances are quite attractive, everyone speaks English - and although the application to Farmatec has to be in Dutch - IGJ inspections can be conducted in English.

Another benefit is the large number of consultant RP's in the Dutch market. Where other countries such as Spain, Germany and Denmark have a shortage of contract RP's; the Netherlands has many.

Starting a company is cheap in the Netherlands, an LLC (limited liability company) (known as a "Besloten Vennootschap") could be established for as little as €1500.-.

These factors combined make for low barriers to entry.

Obviously, not only post-Brexit British organizations are establishing WDA's in the Netherlands - so are domestic companies and those of surrounding nations such as Belgian and German companies.

It's not just the paperwork that counts

Companies that are new to the pharmaceutical sector often think that the GMP and GDP are mostly about the paperwork. Writing a number of SOP's - performing a quick risk assessment and ensuring that the license application is in order should do the trick.

Often, the GxP's are seen as comparable to ISO in it's implementation. ISO quality systems focus on quality, continuous improvement and customer satisfaction. The ISO quality system is a bit more flexible in it's approach though - and mostly driven by market demand.

The GMP and GDP are stricter. Although there is some flexibility in the application of the GMP and GDP guidelines, the government most often will require companies to follow industry standards, the inspectorates base their opinions not only on the regulatory requirements - but also on how the industry implements these requirements.

If most companies choose a specific approach, the inspectorates tend to see it as "the way to go". Unless those companies are all wrong, which doesn't happen often.

What smaller, new entrants to the pharmaceutical market don't see are the large teams of Subject Matter Experts, QA, QC and production personnel that formulate these approaches to the guidelines, that the government subsequently adopts as industry standards against which they will inspect.

Another factor is compounding improvements. Many established companies have perfected their systems over the years. A basic change control procedure may have been finessed over the years to be perfectly functioning. When inspectorates see such a finessed system, they will expect a (somewhat) similar system for startups. The inspectorate cannot use double standards.

The common argument

An often-cited argument for insufficient investment in quality is: "We're just a startup, how can we be expected to comply with all that GDP stuff?" Others claim that the Dutch healthcare inspectorate is unreasonable, saying, "They only look at the letter of the law." This us-versus-them attitude is counterproductive and usually stems from a misunderstanding of the inspectorate's role. The inspectorate's purpose is not to police but to safeguard.

The inspectorate was established to ensure patient safety and public health are maintained at acceptable levels. They approve or reject license requests based on a company’s ability to uphold quality, safety, and availability of medicinal products. Regardless of the company's size, its decisions can impact the entire supply chain.

There are plenty of examples where singular links in the supply chain can have an impact on the quality, safety, efficacy or availability of medicinal products:

In 2017, the CDC found that improper vaccine storage and handling practices in the U.S. led to compromised vaccines. Vaccines require strict temperature control, and deviations can render them ineffective. This situation resulted in significant financial losses and potential public health risks as patients received vaccines that may not have provided immunity as expected.

In 2018, the UK faced a serious incident where a batch of blood products was found to be contaminated during storage and distribution. This contamination led to a halt in transfusions and recalls.

In 2019, the NHS faced a critical shortage of certain medications because of failures in the distribution chain. The shortage was primarily due to logistics issues and poor inventory management, which affected patients relying on these medications for chronic conditions.

When the inspectorate finds that a company does not fully understand the importance of quality or the impact it can have on the supply chain, they may decide not to grant a license yet.

You may be able to perform tasks you don't fully comprehend, but you will not be able to identify failure points accurately or deal with them effectively. This is the biggest risk in the supply chain: not knowing what can go wrong and where. Such gaps in knowledge may lead to quality defects and the inability to supply medicinal products.

Doing it right is cheaper

Some companies try to "reason away" GDP requirements, seeking shortcuts that initially seem to save time and money. However, nothing is more expensive than having to argue decisions with an inspector, knowing you're wrong.

Ideally, inspections should proceed smoothly, with arguments presented from a position of strength—knowing you did the right thing and can explain why. This approach builds confidence with the inspector.

It's essential to avoid discussions where you knowingly took shortcuts to save money or time. These often lead to expensive repair projects that consume more resources than initially saved. Inspectors are not always right and vary in their evaluations. It's important to defend your actions where appropriate, but always from a position of strength. If you're wrong, admit it. Demonstrating an understanding of your mistakes increases your chances of obtaining a WDA license more than stubbornly defending wrong decisions.

Conclusion

Navigating the complex landscape of obtaining a Wholesale Distribution Authorization (WDA) license is no easy feat, especially for startups. However, cutting corners and attempting to "hack" your way into compliance can lead to severe consequences, not only for the company but also for public health and safety. The inspectorate's role is to ensure that companies uphold the highest standards of quality, safety, and availability of medicinal products, regardless of their size.

When a company lacks a thorough understanding of these standards, it risks making decisions that can negatively impact the entire supply chain. Examples of storage and distribution mishaps, such as compromised vaccines, contaminated blood products, and medication shortages, underscore the importance of strict adherence to guidelines.

It's crucial to approach inspections and regulatory requirements with a mindset of compliance and improvement. Taking shortcuts may seem like a quick fix, but it often results in costly rectifications and potential harm to patients. Engaging with the inspectorate from a position of knowledge and integrity not only increases the likelihood of obtaining a WDA license but also reinforces the commitment to maintaining high standards in the pharmaceutical industry.

Ultimately, doing it right from the start is more cost-effective and builds a foundation of trust and reliability with regulators and stakeholders. Admitting mistakes and showing a willingness to learn and improve can significantly enhance a company's credibility and operational success.